of electric vehicles today have permanent magnet (PM) motors.

PM motors are problematic because there’s a supply shortage of Rare Earth Elements (REE). That’s why the industry is moving toward RE-free motors.

More For Less

Dynamic Motor Drive (DMD) removes reliance on REE and gives you more efficiency at a lower cost.

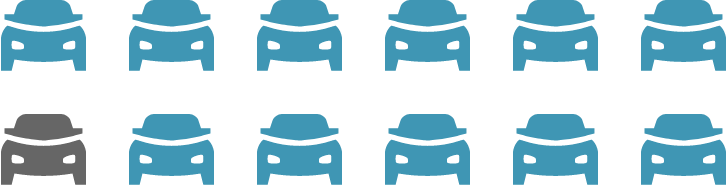

When torque requests are low, DMD pulses the magnetic field at optimal efficiency. A conventional motor running continuously can’t deliver as much efficiency.

With the move to electrification, RE magnet dependence, range anxiety and battery costs are still looming issues. DMD provides an affordable software efficiency solution, free from the environmental and cost impacts of RE metals.

What Makes DMD Different

Scalable, transparent, and straight forward integration

High efficiency solution at a lower cost than alternatives

Accelerates transition to environmentally friendly RE-free motors

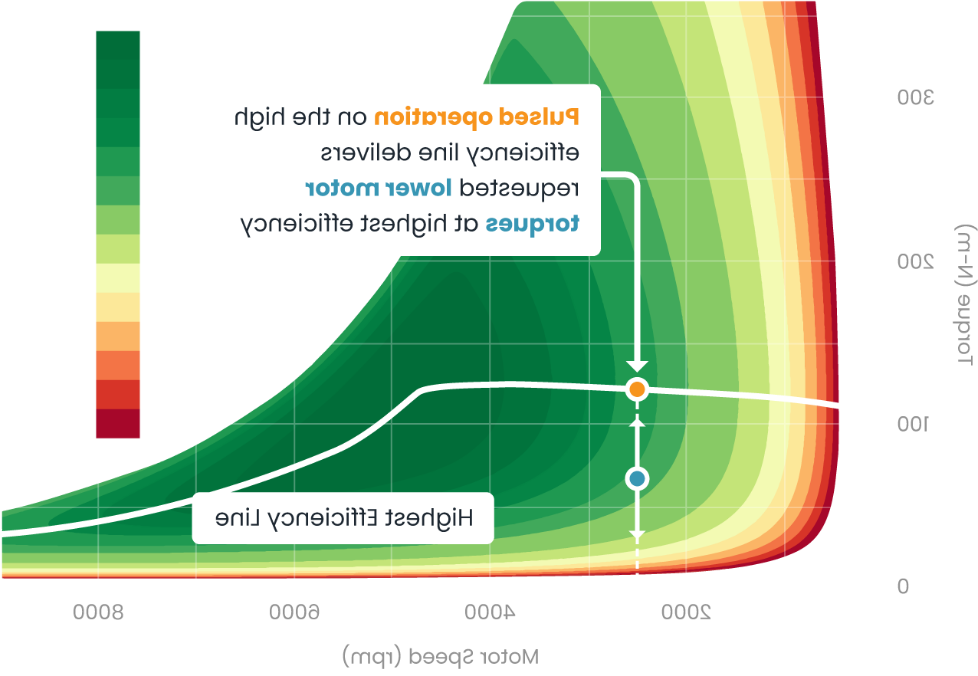

DMD Reduces System Losses

DMD makes systems more efficient by reducing core and inverter switching losses. Results? 25% reduction in energy loss.

Tula Publications

Software Solution Boosts EV’s Evolution

DMD is a software solution that improves Externally Excited Synchromous Motors (EESMs) and other RE-free motors. DMD software completes existing systems, making EESMs as efficient at low speeds as they are at high speeds. Now you can get efficiency without RE.

Motors

Use no magnets and are primarily secondary drives

Low Efficiency

Internal Permanent Magnet Machines

Dominate EVs but require expensive problematic rare earth elements (REE)

High Efficiency

Externally Excited Synchronous Motors

Replace REE magnets with copper reducing cost with equivalent performance

High Efficiency

DMD

Technology in Action

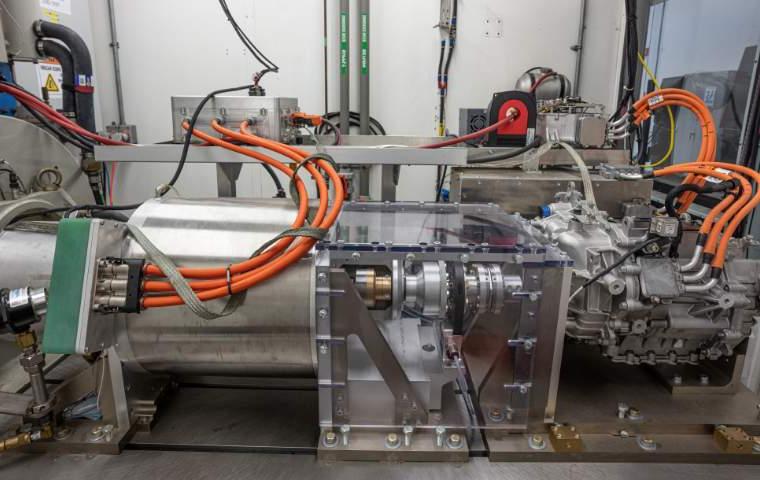

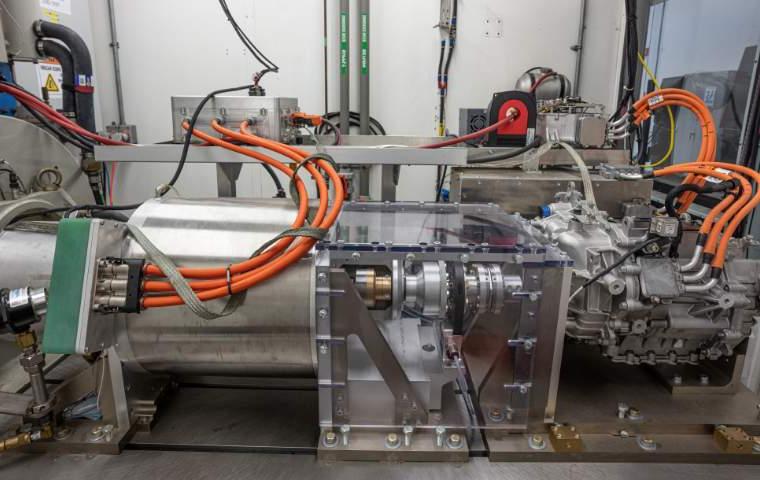

Dynamometer work has proven DMD value; vehicles demonstrate on-road drivability and customer acceptance.

Tula provides design consulting, R&D and IP licensing services to its customers as well.

Our 150kW vehicle traction-motor development dyne is proving efficiency gains.

Dynamic waveform control eliminates perception of DMD in vehicle operation.

DMD for Industry: Transition to a Better Future

DMD also helps Industry experience a significant boost in efficiency, saving energy and accelerating the transition to a future without rare earth materials.

Induction Motors

Require no magnets and dominate the industrial market

Low Efficiency

Induction Motors

Meet latest IE5 regulations with power electronics

Medium Efficiency

Synchronous Reluctance Machines

Low-cost and robust with better efficiency than induction motors

High Efficiency